We are the most modern furniture-producing factory in the Czech Republic

Operating premises with an area of 69,500 m2

What others consider outstanding is the everyday standard at HANÁK

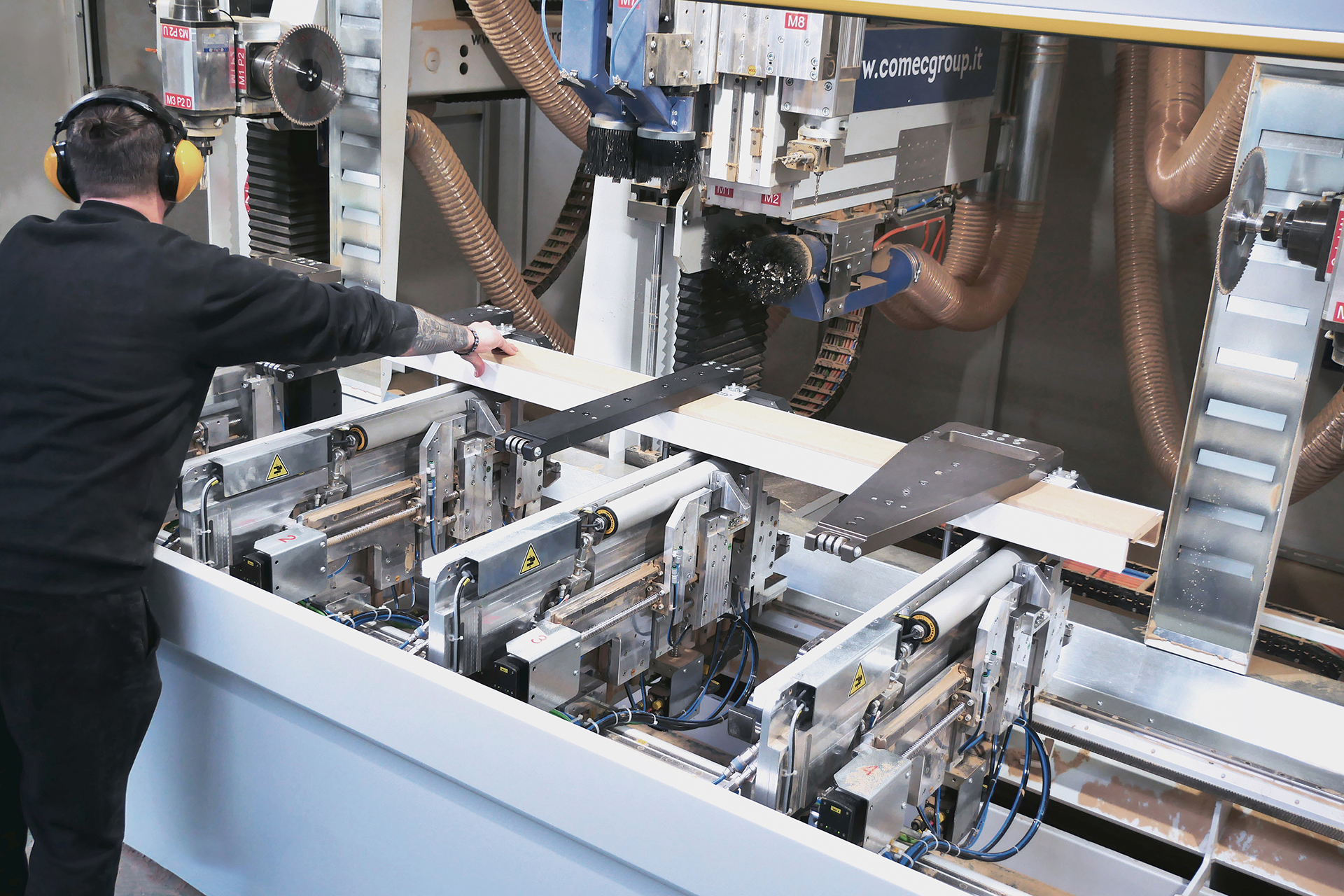

Our technological leadership and production capacities enable us to realise both individual and large-scale production for development projects. With our complete machinery, we are one of the best equipped furniture manufacturing companies in Europe.

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/nejmodernejsi_lakovaci_centrum/hanak-nabytek-vyroba-nejmodernejsi_lakovaci_centrum__1_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/nejmodernejsi_lakovaci_centrum/hanak-nabytek-vyroba-nejmodernejsi_lakovaci_centrum__2_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/nejmodernejsi_lakovaci_centrum/hanak-nabytek-vyroba-nejmodernejsi_lakovaci_centrum__4_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/nejmodernejsi_lakovaci_centrum/hanak-nabytek-vyroba-nejmodernejsi_lakovaci_centrum__5_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/nejmodernejsi_lakovaci_centrum/hanak-nabytek-vyroba-nejmodernejsi_lakovaci_centrum__6_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/nejmodernejsi_lakovaci_centrum/hanak-nabytek-vyroba-nejmodernejsi_lakovaci_centrum__8_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/4/7/csm_hanak-nabytek-vyroba-nejmodernejsi_lakovaci_centrum__9__caa1b0b1cb.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/1/c/csm_hanak-nabytek-vyroba-nejmodernejsi_lakovaci_centrum__10__dc718e8e72.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/nejmodernejsi_lakovaci_centrum/hanak-nabytek-vyroba-nejmodernejsi_lakovaci_centrum__3_.jpg)

The most modern painting centre

7,000 m2 of state-of-the-art paint

The painting technologies used in the 7,000 m2 shops match the standard of world-class production plants. By combining many years of experience and continuous investment in development, we always achieve the best results.

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/roboticke_lakovani/hanak-nabytek-nejmodernejsi-technologie-lakovani__5_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/roboticke_lakovani/hanak-nabytek-nejmodernejsi-technologie-lakovani__6_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/f/3/csm_hanak-nabytek-nejmodernejsi-technologie-lakovani__12__505a0e33f3.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/8/5/csm_hanak-nabytek-nejmodernejsi-technologie-lakovani__8__dff0d7f711.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/f/3/csm_hanak-nabytek-nejmodernejsi-technologie-lakovani__10__2cc236f3aa.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/9/d/csm_hanak-nabytek-nejmodernejsi-technologie-lakovani__7__ade4b44126.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/roboticke_lakovani/hanak-nabytek-nejmodernejsi-technologie-lakovani__1_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/roboticke_lakovani/hanak-nabytek-nejmodernejsi-technologie-lakovani__3_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/6/c/csm_hanak-nabytek-nejmodernejsi-technologie-lakovani__9__04d7b2b246.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/a/8/csm_hanak-nabytek-nejmodernejsi-technologie-lakovani__13__66510f694e.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/roboticke_lakovani/hanak-nabytek-nejmodernejsi-technologie-lakovani__4_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/roboticke_lakovani/hanak-nabytek-nejmodernejsi-technologie-lakovani__2_.jpg)

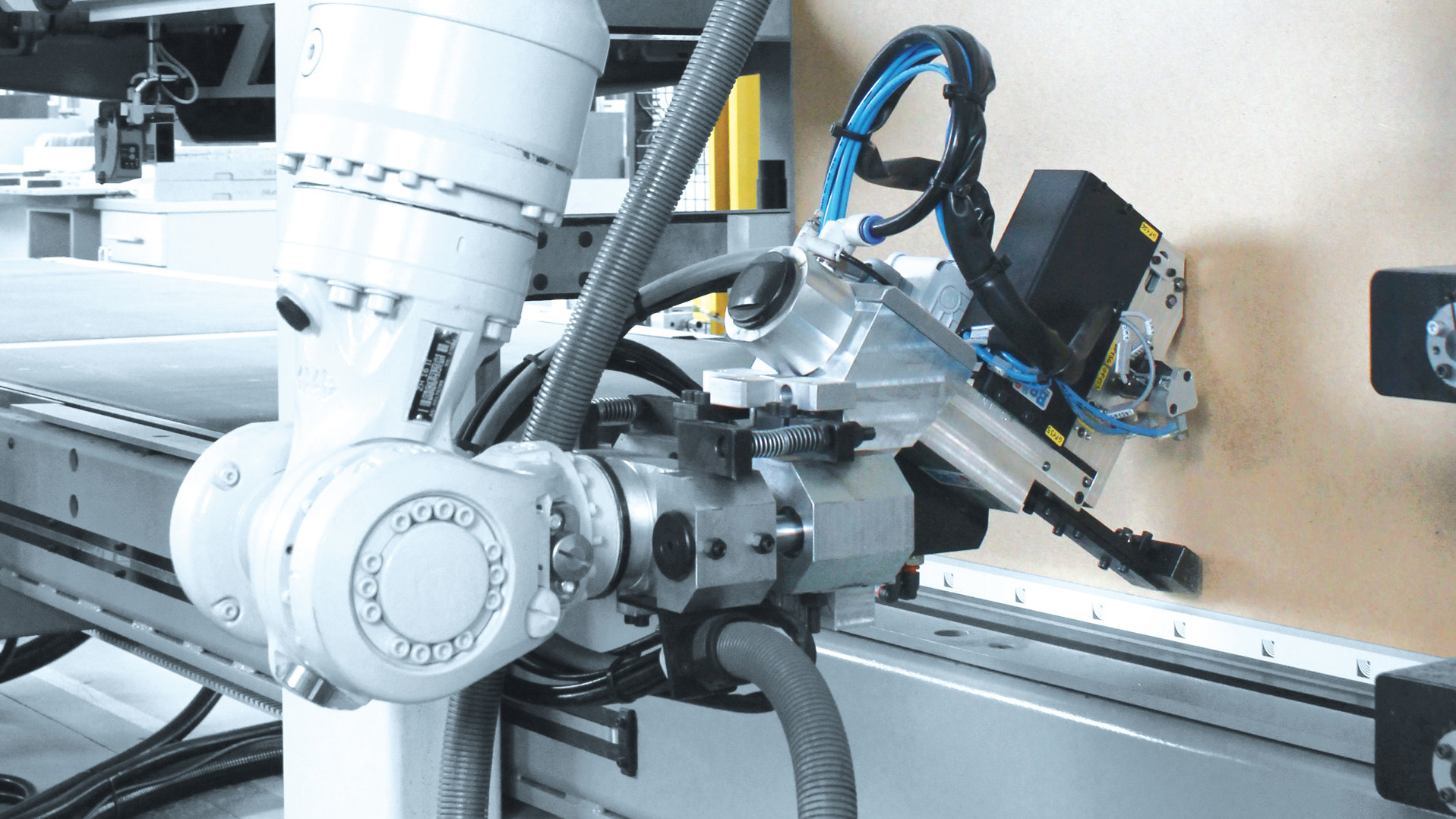

Robotic coating

A fully automated robotic coating machine is the only solution to ensure that each coat is sprayed uniformly over each varnished furniture element, which creates flawlessly varnished and durable surfaces.

With our over 25 years of experience in lacquer technologies, we can confidently produce furniture of the highest quality.

For furniture HANAK we apply transparent or pigmented NANO varnishes from a deep 5% matt to a 100% high gloss.

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/centrum_pro_aplikaci_nano_laku/hanak-nabytek-vyroba-centrum_pro_aplikaci_nano_laku__2_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/centrum_pro_aplikaci_nano_laku/hanak-nabytek-vyroba-centrum_pro_aplikaci_nano_laku__4_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/centrum_pro_aplikaci_nano_laku/hanak-nabytek-vyroba-centrum_pro_aplikaci_nano_laku__5_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/centrum_pro_aplikaci_nano_laku/hanak-nabytek-vyroba-centrum_pro_aplikaci_nano_laku__1_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/1/c/csm_hanak-nabytek-vyroba-centrum_pro_aplikaci_nano_laku__6__851a50bb8d.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/centrum_pro_aplikaci_nano_laku/hanak-nabytek-vyroba-centrum_pro_aplikaci_nano_laku__3_.jpg)

Centre for the application of NANO varnishes

The most modern painting centre for the application of NANO varnishes in Europe ensures the highest quality surface treatment of furniture, without the slightest human intervention in the coating process.

Varnishing takes place under the monitoring of thousands of special sensors, checking the maximum accuracy of production.

The length of the coating centre is 50 metres.

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__2_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__4_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__3_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__17_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__20_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__10_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__21_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__22_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__5_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/b/7/csm_hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__7__a3c7dcc4a9.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__11_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__12_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__13_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__19_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodernejsi_vyroba.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__25_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__18_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__1_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__16_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__9_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/expedice_a_baleni/hanak-nabytek-vyroba-baleni__2_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__23_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__15_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/vyroba_dvere/hanak-nabytek-nejmodejrnejsi_vyroba-interierove_dvere__14_.jpg)

Production of interior doors

We are the only production plant in Europe that produces interior doors in the same finishes as other furniture, which allows the perfect pairing of all interior areas according to the HANÁK Interior Concept.

The craftsmanship of the door frame and the maximum durability of the door leaf construction, in combination with a luxurious surface treatment in the form of varnish or natural veneer, make HANÁK interior doors unique within the market.

We manufacture doors:

- For interiors, fireproof and acoustic doors

- For hotels, fireproof and interior doors

- Special interior door

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/slim-line/hanak-nabytek-vyroba-technologie-slim_line__3_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/slim-line/hanak-nabytek-vyroba-technologie-slim_line__4_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/slim-line/hanak-nabytek-vyroba-technologie-slim_line__1_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/6/6/csm_hanak-nabytek-technologie-slim_line__7__16e7924154.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/slim-line/hanak-nabytek-vyroba-technologie-slim_line__2_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/slim-line/hanak-nabytek-vyroba-technologie-slim_line__6_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/slim-line/hanak-nabytek-vyroba-technologie-slim_line__5_.jpg)

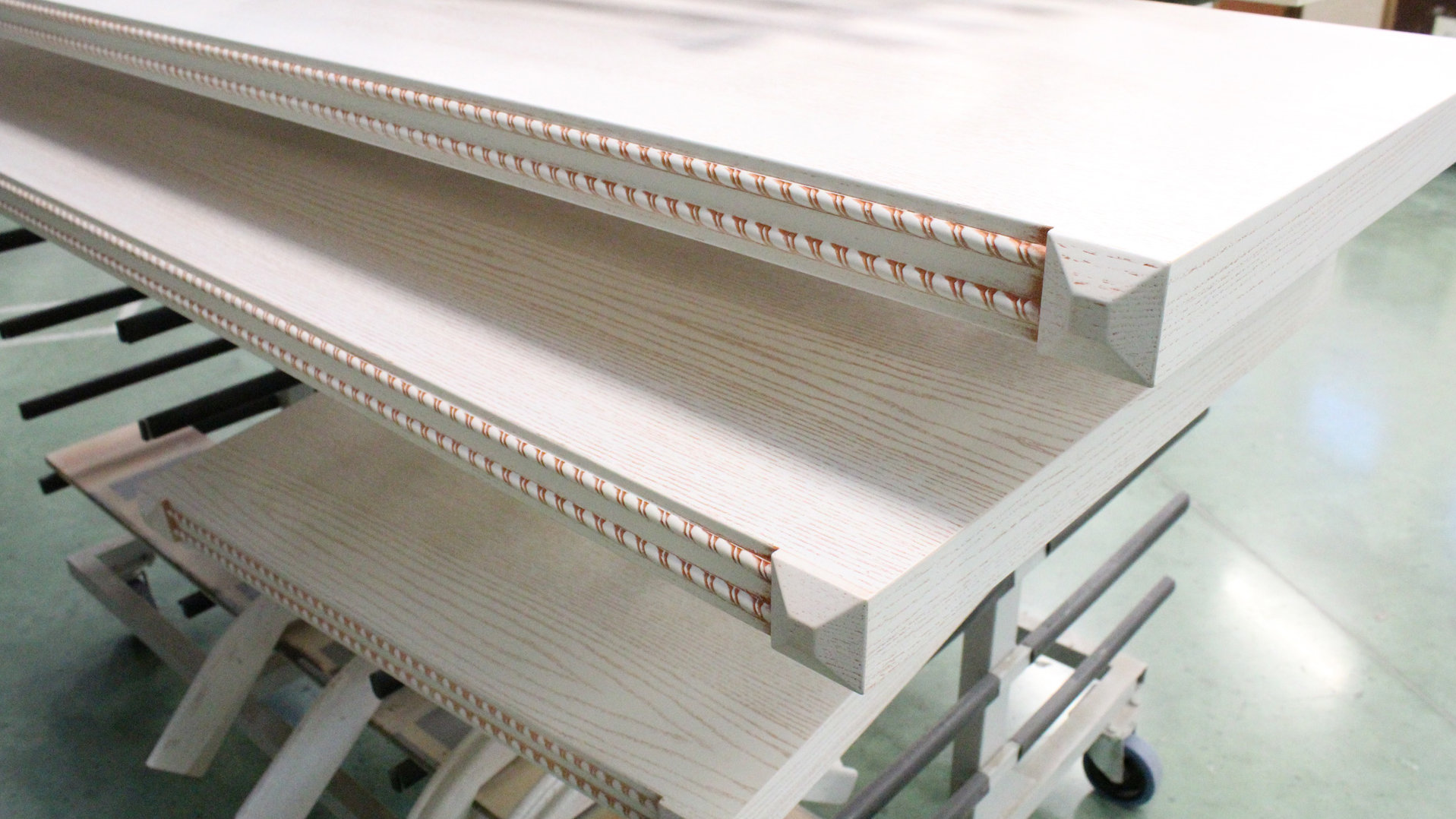

SLIM-LINE technology

The patented "SLIM-LINE" edging technology, the PUR-TERMOSET, is only used by a few manufacturers in Europe.

This creates a water-resistant connection and prevents damp and water from entering the cupboard body. Every part of our product offer comprises edges glued with this technology.

The new PUR-TERMOSET technology outshines the previous standard of banding carried out with EVA-TERMOPLAST glues in all parameters.

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/rucni_vyroba/hanak-nabyte-rucni_vyroba.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/5/4/csm_hanak-nabytek-vyroba-sesivani_dyhy__4__341cf6d9ae.jpg)

Handmade craft production

We have craft and technology at heart. We are convinced that one cannot work without the other.

Elegant decorative straight and curved strips, rustic columns, cornices and shelves, created by master carpenters for years.

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/4/2/csm_hanak-nabytek-vyroba-sesivani_dyhy__1__e1b618725e.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/3/2/csm_hanak-nabytek-vyroba-sesivani_dyhy__3__aa39a464f9.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/1/5/csm_hanak-nabytek-vyroba-sesivani_dyhy__2__15f7648925.jpg)

Veneer cutting and stitching

The art of veneer assembly allows us to deliver orders in premium quality with a figural continuity of the veneer dominating throughout the entire interior.

The wood-grain continuity in the entire product is best seen in the panelling for interior doors, where the continuity of the grain can even be several metres long.

Hand-made patina and gilding

Hand patination, scratching or hand gilding are highly valued art techniques used in the production of rustic HANÁK products.

The high proportion of our masters' handwork makes each piece of furniture original.

Shape pressing

We use high-frequency shape pressing in the production of rounded furniture profiles. We produce them in top quality and without the effect of subsequent deformation.

We consider shape pressing to be a special and independent discipline in furniture production.

You will find rounded furniture profiles in our kitchens, living rooms, bedrooms, bathrooms and children's rooms.

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/4/a/csm_hanak-nabytek-vyroba-kompletacni_linka__7__ffcee40511.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/kompletacni_linka/hanak-nabytek-vyroba-kompletacni_linka__4_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/2/a/csm_hanak-nabytek-vyroba-kompletacni_linka__3__26dc14b075.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/6/1/csm_hanak-nabytek-vyroba-kompletacni_linka__2__2dcca30d91.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/b/3/csm_hanak-nabytek-vyroba-kompletacni_linka__6__4fe8100158.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/user_upload/vyroba/kompletacni_linka/hanak-nabytek-vyroba-kompletacni_linka__5_.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/9/e/csm_hanak-nabytek-vyroba-kompletacni_linka__1__589946e355.jpg)

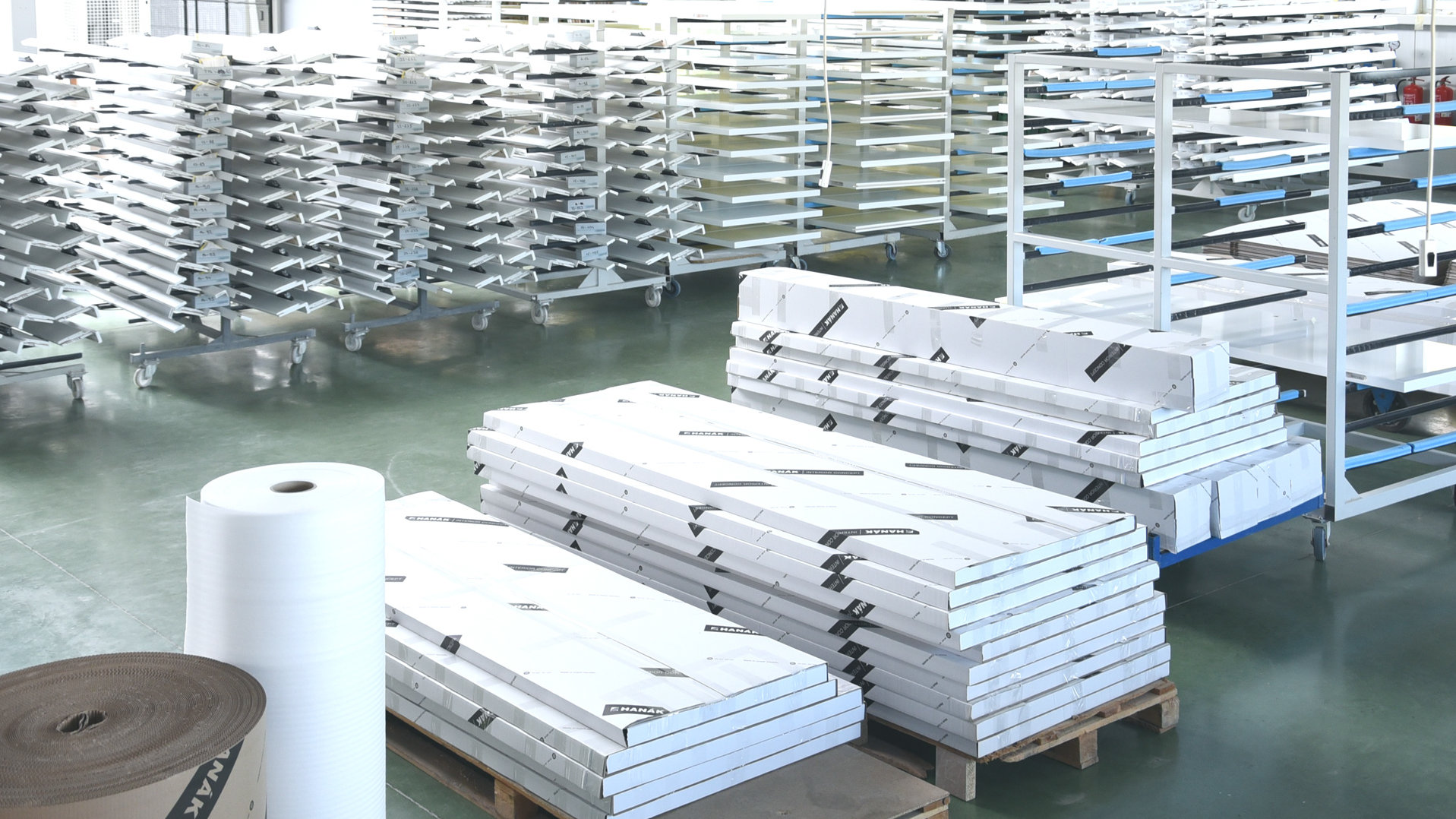

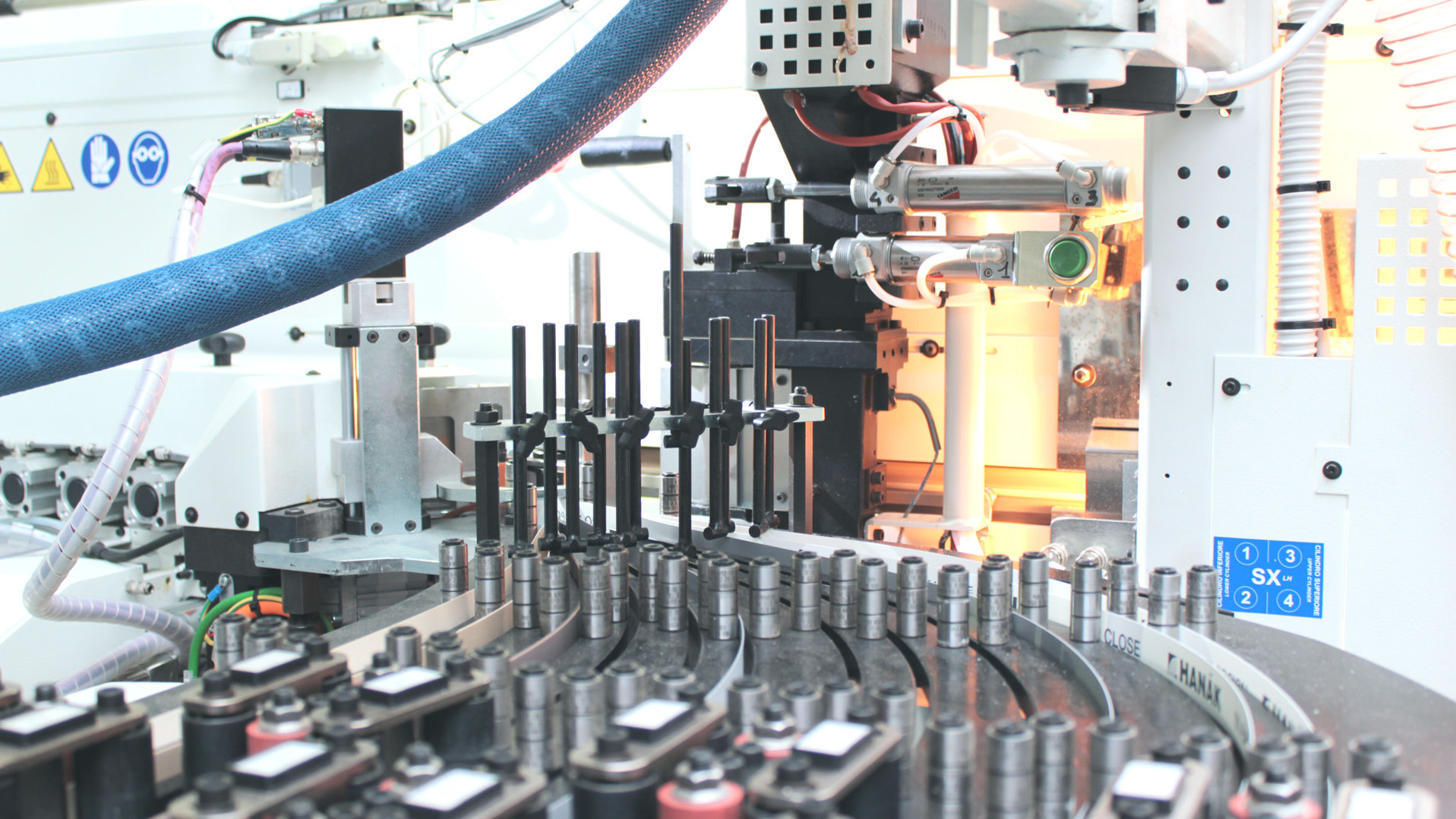

Assembly robotic line

A place where complete units are created from individual parts.

Robotic furniture assembly technology ensures perfect assembly of furniture modules to one tenth of a millimetre. The assembly precision will be reflected in the final appearance and functionality of the furniture after the assembly of the work.

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/c/a/csm_hanak-nabytek-vyroba-expedice_4d2e4bf18e.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/1/3/csm_hanak-nabytek-vyroba-baleni__3__810ecd053f.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/4/b/csm_hanak-nabytek-vyroba-nejmodernejsi_lakovaci_centrum__5__5df0a5f430.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/c/3/csm_hanak-nabytek-vyroba-baleni__1__f784a7651c.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/e/2/csm_hanak-nabytek-vyroba-baleni__4__36391e20c8.jpg)

![[Translate to Angličtina:] [Translate to Angličtina:]](/fileadmin/_processed_/6/d/csm_hanak-nabytek-vyroba-nejmodernejsi_lakovaci_centrum__7__64a6bea8bf.jpg)

Expedition of furniture to the whole world

Every day, thousands of furniture modules leave the production plant, heading to countries around the world.

The trucks go outside the Czech Republic mainly to the USA, England, Belgium and others.